In the world of machinery, few components are as crucial yet often overlooked as compressor rings. These essential elements play a pivotal role in the functionality and efficiency of various types of compressors, from those in your household air conditioners to the ones powering large industrial systems. Compressor rings are not just mere parts; they are the backbone of the compression process.

This article delves into the intricacies of compressor rings – exploring their design, functionality, types and their role in the broader mechanical landscape. Join us as we unravel the importance and complexity of these seemingly small but extraordinarily vital components.

Understanding Compressor Rings

To understand compressor rings, it is crucial to first grasp the concept of compressors. Compressors are mechanical devices that increase the pressure and density of a gas by reducing its volume. They work on the principle of Boyle’s law – which states that the volume of a gas decreases as its pressure increases at a constant temperature.

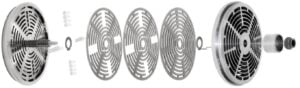

Also known as piston rings, they are circular metal rings designed to form a seal between the piston and cylinder in a compressor. They play a critical role in maintaining the integrity of the compression process by preventing gas leakage and ensuring efficient operation.

The design of compressor rings is carefully crafted to withstand high pressures and temperatures while maintaining tight tolerances. The most common types of compressor rings are made from cast iron or stainless steel, with some specialized applications using materials such as carbon fiber or ceramic.

Piston Rings in a Combustion Engine or Motor

Piston rings have been used in combustion engines or motors for centuries, with their primary role being to seal the combustion chamber and prevent gas leakage. They also help regulate oil consumption by scraping excess oil from the cylinder walls.

In a typical combustion engine, there are three types of piston rings – compression ring, scraper ring, and oil control ring. The compression ring is located closest to the combustion chamber and is responsible for sealing the gases in the cylinder.

The scraper ring is located above the compression ring and helps prevent oil from entering the combustion chamber. The oil control ring is situated at the bottom of the piston and helps regulate oil distribution on the cylinder walls.

Maintaining Gas Compression

In a compressor, the main function of piston rings is to maintain gas compression by forming a tight seal between the piston and cylinder walls. This allows for efficient transfer of energy from the motor or engine to the compressed gas.

To ensure effective sealing and minimal leakage, compressor rings must be carefully designed and manufactured with precision. They also require regular maintenance and replacement to avoid any potential leakages and maintain optimal compression performance.

Lubrication Control

Lubrication control is achieved through the use of specialized oil control rings, which help distribute a consistent and appropriate amount of oil onto the cylinder walls. Proper lubrication is essential for reducing friction between the piston and cylinder walls, ensuring smooth operation and prolonging the life of the compressor. Oil control rings prevent excessive oil consumption and maintain a thin film of oil on the walls, while also preventing any potential buildup that may interfere with the sealing function of the compression ring.

Heat Transfer

A compressor ring also play a role in heat transfer within the engine or motor. As they come into contact with the hot gases and cylinder walls, piston rings absorb some of the heat and transfer it away from the combustion chamber.

This helps prevent overheating, which can lead to engine damage and reduced performance. The design of compressor rings takes into account their ability to withstand high temperatures and effectively transfer heat away from the engine.

Materials used in Compressor Rings

As mentioned earlier, the most common materials used for this type of rings are cast iron and stainless steel. Cast iron is a durable and cost-effective option that can withstand high temperatures and pressures. Stainless steel offers similar properties but with added corrosion resistance.

In specialized applications where extreme conditions are expected, materials such as bronze and titanium may be used. These materials offer superior strength and durability, but they also come at a higher cost.

Proper Installation and Maintenance

To ensure optimal performance of compressor rings, it is vital to properly install them in the engine or compressor. This includes ensuring precise measurements, clean surfaces, and proper lubrication during installation.

Regular maintenance is also crucial for ensuring the longevity of compressor rings. This includes inspecting and replacing worn or damaged rings, as well as regularly cleaning and lubricating them.

Proper installation and maintenance not only prolong the life of compressor rings but also help prevent any potential damage to the engine or compressor due to leakage.

Types of Compressor Rings

There are two main types of compressor rings – piston rings and oil control rings. Piston rings are located on the piston head and prevent gas leakage from the combustion chamber into the crankcase. Oil control rings, on the other hand, regulate the amount of oil that lubricates the cylinder walls and piston head.

Piston rings can be further categorized into compression rings, wiper or scraper rings, and oil control rings. Compression rings are responsible for sealing the gap between the piston and cylinder wall to prevent gas leaks during combustion. Wiper or scraper rings remove excess oil from the cylinder walls, preventing it from entering the combustion chamber. Oil control rings regulate the amount of oil on the cylinder walls to ensure proper lubrication while reducing emissions.

Importance of Compressor Rings

These types of rings are a crucial component in ensuring the efficiency and longevity of compressors. Without them, gas leakage can occur, resulting in reduced performance and potential damage to other components. Properly functioning compressor rings also contribute to energy savings and lower maintenance costs.

Maintenance and Replacement

Like any other mechanical component, compressor rings require regular maintenance to ensure optimal performance. Regularly checking for wear and tear, cleaning, and proper lubrication can extend the life of compressor rings. However, even with proper maintenance, compressor rings will eventually need replacement due to natural wear.

The frequency of replacement depends on various factors such as operating conditions, type of compressor, and the quality of rings used. It is essential to follow manufacturer recommendations for replacement intervals and use high-quality rings from reputable suppliers.

Conclusion

In summary, compressor rings play a critical role in maintaining the efficiency and performance of compressors. Regular maintenance and proper replacement are necessary to ensure optimal functioning and avoid potential damage or safety hazards.

By understanding their importance and taking proper care, these rings can contribute to cost savings and prolong the life of compressors. So, it is important for individuals working with compressors to have knowledge about them and their maintenance in order to ensure optimal performance of the equipment.