Maintaining air purity is crucial in sensitive applications where even the tiniest oil droplet can lead to contamination of products or equipment malfunction. Depending on the specific use case, different compressed air technologies offer distinct advantages over others. Luckily, different manufacturers offer the flexibility of multiple oil-free compressor technologies to meet your unique requirements. These range from rotary screws to centrifugal, scroll, and reciprocating oil-free air compressors. In this article, we’ll explore the basics of oil free air compressors and their applications.

What are Oil-Free Air Compressors?

Oil-free air compressors are specially designed to produce clean compressed air without any traces of lubricating oil. This is crucial in applications where the compressed air must not come into direct contact with products or processes, such as in the food and pharmaceutical industries.

Air compression typically happens in the compression chamber–and most air compressors naturally have lubricating oil in the compressing chamber to optimize their operations.

Oil-free compressors, unlike their oil-lubricated compressors counterparts, do not have any oil in the compression chamber. With these oil-less air compressors, there is no oil throughout the entire system, eliminating the risk of oil contamination in the air.

Types of Oil-Free Air Compressors

Reciprocating Compressors

Reciprocating oil-free compressors are also known as piston compressors. How do they operate? Rather straightforward; they use a motor-driven piston that moves up and down within a cylinder to compress the air.

During an intake stroke, the piston moves downward, creating a vacuum that draws in air through an inlet valve. When the piston moves upward, it compresses the air and pushes it out of the chamber through an outlet valve.

One major advantage of reciprocating oil-free air compressors is their simple design which makes them easy to maintain and repair. They are also relatively affordable compared to other types of oil-free compressors.

Rotary Screw Compressors

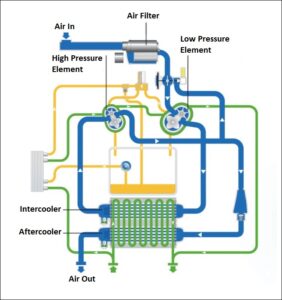

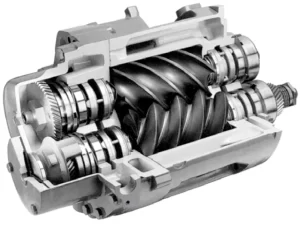

Rotary screw compressors are widely used in industrial setups because they are very efficient, reliable, and generally small in size.

As the name suggests, they use rotors instead of a piston to compress air. This type of compressor uses at least two rotors with matching profiles that rotate in opposite directions to compress the air.

As the rotor blades turn, they create a series of air pockets that become smaller as they move toward the discharge end, compressing the air in between them.

One major advantage of rotary screw oil-free air compressors is their ability to continuously supply compressed air without interruption. This attribute makes them ideal for heavy-duty applications. They also have a smaller footprint compared to reciprocating compressors, and therefore, are space-efficient.

Scroll Compressors

Like rotary screw oil-free compressors, scroll oil-free air compressors are also commonly used in industries where a steady supply of high-quality compressed air is required. However, there’s a slight difference in the working mechanism of these two types.

Scroll compressors use two spiral-shaped elements, one stationary and the other rotating to compress air. As the moving spiral orbits around the fixed one, it creates a pocket that reduces in size as it moves toward the center, compressing the air inside.

This type of compressor is largely preferred for its quiet operation, low maintenance requirements, and oil-free compressed air output.

Scroll compressors also have fewer moving parts, which means they have relatively lower energy consumption and longer lifespan.

Centrifugal Compressors

Last, but not least, are the centrifugal oil-free air compressors. These ones work on a totally different principle from the three outlined above. The first part of these compressors uses high-speed impellers to draw and accelerate air, while the second part decelerates the air to create air pressure.

This results in an oil-free, low-pressure compressed air supply that is suitable for a wide range of heavy-duty applications.

Centrifugal compressors are best for industrial setups that require colossal amounts of compressed air. They are, therefore, ideal for large-scale operations like power plants, refineries, and manufacturing facilities.

Applications of Oil-Free Air Compressors

Medical and Healthcare Industry

These compressors play a vital role in the medical and healthcare industry. These compressors provide clean, uncontaminated air, which is crucial for maintaining sterility and ensuring patient safety. They are used in various medical applications such as for powering surgical tools, ventilation systems, and in the delivery of medical gases. Additionally, oil-free air compressors are utilized in dental practices, hospitals, and other healthcare facilities for driving medical devices and maintaining a clean and sterile environment.

Food and Beverage Industry

In the food and beverage industry, purity is the topmost priority. Oil-free air compressors are employed in various processes such as in the packaging of food and beverages, fermentation, aeration, and filling lines. These compressors ensure that the air used in these processes is clean and devoid of any oil contaminants that could compromise quality or safety. This not only assures the production of safe and hygienic products but also helps in maintaining compliance with stringent industry regulations.

Electronics Manufacturing

Electronics manufacturing requires a high degree of precision and cleanliness, making oil-free air compressors an essential tool in this industry. These compressors are typically used in PCB manufacturing, component insertion, pick and place machines, and general plant air. The absence of oil in the compressed air prevents contamination of sensitive electronic components, ensuring high product quality and reducing the risk of product failure.

Pharmaceutical Industry

Oil-free air compressors are indispensable in the pharmaceutical industry where they are used in a variety of applications including aeration, tablet production, packaging, and material handling. Maintaining clean, oil-free air is crucial in these applications to prevent the contamination of pharmaceutical products. This ensures the safety and efficacy of the drugs and helps the industry comply with stringent quality control standards.

Laboratory Applications

Laboratories often require a reliable source of clean, oil-free air for various applications, making oil-free air compressors an ideal choice. They are used in a variety of laboratory applications, such as driving pneumatic systems, performing analytical tests, and in the operation of fume hoods. The provision of oil-free air ensures the integrity of research outcomes by preventing contamination, thereby facilitating accurate and reliable results.

Comparing Oil-Free Other Compressors With Oil-Lubricated Compressors

Oil-lubricated compressors, while similar to oil-free compressors in many aspects, have some critical differences. The most obvious of many differences is that oil-lubricated compressors use an oiling system where the air is mixed with oil for lubrication, sealing, and cooling purposes while an oil-free compressor doesn’t.

Instead, oil-free compressors use alternative methods, such as water or air for lubrication, sealing, and cooling. This results in an unadulterated and better quality compressed air.

Maintenance

Generally, oil-free air compressors generally require less maintenance compared to their oil-lubricated counterparts. The absence of oil in the compression system eliminates the need for oil changes and filter replacements.

That aside, it is also crucial to note that by design, oil-free compressors have fewer moving parts, resulting in less wear and tear. This ultimately reduces the frequency of maintenance and repairs needed, making them a more cost-effective option.

However, it is important to note that regular maintenance is still necessary for oil-free compressors to ensure their optimal performance. This includes monitoring the air quality, checking for any worn or damaged parts, and keeping the compressor clean.

How to Maintain Oil-Free Air Compressors

As air compressors continue to supply clean and pure air, it is essential to properly maintain them to ensure their longevity and efficiency. Below are some general maintenance steps for oil-free compressors:

1. Regular Inspection

Routine inspection is a must if you want your compressor to serve you optimally for a long time. This involves checking the compressor for any visible signs of wear and tear, including rust, cracks, and leakages.

Fortunately, most brands provide easy-to-follow inspection guidelines for their products.

It is also important to monitor the compressor’s performance— changes in noise levels, pressure output and energy consumption as these could indicate a potential issue.

2. Cleaning and Replacing Filters

Air filters play a crucial role in preventing dust, dirt, and other airborne contaminants from entering the compressor, thus ensuring the delivery of clean compressed air. It is good practice to regularly replace or, at least, clean compressor filters.

Established brands, for instance, recommend cleaning the air filters every 2000 hours of use to maintain optimal performance. When the filters get clogged over time, they should be replaced to prevent poor operational efficiency and compressor damage.

3. Monitoring and Controlling Temperature

Nearly all oil-free air compressors generate some heat during operation. If not properly managed, excessive heating can lead to damage and reduced compressor lifespan.

Therefore, it’s essential to monitor and regulate the compressor’s temperature. This shouldn’t worry you too much though as most modern air compressors will automatically shut down when the temperature exceeds a certain threshold..

4. Drainage Systems

As with any compressed air system, moisture is an unavoidable by-product. While oil-free compressors do not have to deal with oil in addition to water, it’s still advisable to regularly drain the moisture from the compressor tank using the provided valve. This prevents rusting and corrosion of internal components, which can lead to malfunctions and reduced lifespan.

Conclusion On Oil-Free Air Compressors

In summary, oil-free air compressors are an excellent choice for applications that require clean and pure compressed air. To keep them working optimally, proper and regular maintenance is a must.

The maintenance includes monitoring energy consumption and output, cleaning and replacing filters, controlling temperature, and maintaining drainage systems. These can significantly extend the compressor’s lifespan and operational efficiency.

While these compressors have their unique features and benefits, understanding and implementing these simple steps can ensure their durability, making them a reliable and cost-effective solution for your compressed air needs.