A compressed air pressure switch is a critical component in systems that generate, distribute, and employ compressed air. Acting as a safety and efficiency monitor, it regulates the pressure levels inside the system in an optimized manner.

When the pressure within the system exceeds or falls below the set points, the switch triggers a response – usually to start or stop the compressor, preventing the potential damage caused by pressure extremes.

By maintaining optimal pressure levels, these switches ensure the efficient operation of the system, minimizing energy waste and safeguarding the longevity of the equipment. Hence, understanding the operations of a compressed air pressure switch is crucial for anyone managing or maintaining a compressed air system.

In this article, we will cover all aspects of compressed air pressure switches to help you gain a comprehensive understanding.

What is a Compressed Air Pressure Switch?

A compressed air pressure switch is an electromechanical device that senses the pressure within a system and triggers a response when it reaches certain set points. It consists of two main components: a sensor element and an electrical switch.

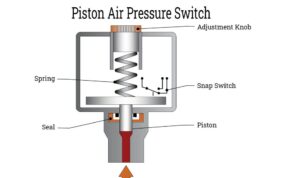

The sensor element is typically a diaphragm or a piston that responds to the pressure changes within the system and converts them into mechanical motion. This motion then acts on the electrical switch, causing it to open or close depending on the pressure levels. The switch, in turn, controls the operation of the compressor or other related equipment.

Types of Compressed Air Pressure Switches

There are two main types of compressed air pressure switches.

1. Electromechanical Pressure Switches

Electromechanical pressure switches are the traditional type used in many compressed air systems. These switches are known for their reliable and straightforward operations. They consist of a mechanical sensor element—typically a diaphragm or a piston—that moves in response to pressure changes within the system. This movement triggers a mechanical actuator, which operates an electrical contact.

When the system’s pressure reaches a certain set point, the sensor element moves, causing the electrical contact to either open or close. This action, in turn, starts or stops the operation of the compressor, effectively managing the system’s pressure levels.

Electromechanical pressure switches are incredibly durable and can withstand harsh operating conditions. However, they do require regular maintenance to ensure their effectiveness and longevity. Their design allows for easy adjustment of pressure set points, making them an adaptable choice for various compressed air systems.

2. Solid-State Pressure Switches

Solid-state pressure switches, also known as electronic pressure switches, are a more modern alternative to electromechanical ones. They use sensors, such as piezoelectric or strain gauge elements to detect pressure changes and convert them into electrical signals.

These signals are then processed by electronic circuits and used to control the operation of the compressor or other equipment.

One of the significant advantages of solid-state pressure switches is their accuracy and precision. They can detect even minor changes in pressure and provide more precise control over the system’s operation. Additionally, they do not have any moving parts, making them less prone to wear and tear, resulting in a longer lifespan.

3. Differential Pressure Switches

Differential pressure switches are designed specifically for applications where the difference between two pressures needs to be monitored. These switches contain two pressure inputs and only activate when there is a significant enough difference between them.

They are commonly used in compressed air systems that have multiple stages of compression, as well as in filtration systems. In these applications, the differential pressure switch can detect any blockages or clogs in the system, preventing potential damage or downtime.

4. Vacuum Pressure Switches

Vacuum pressure switches, as the name suggests, are used to monitor negative pressure or vacuum levels in a system. They work similarly to pressure switches, but instead of detecting increases in pressure, they detect decreases.

These switches are commonly used in applications where a vacuum is essential for the process to function correctly, such as in vacuum pumps or suction systems. They can also be used to detect any leaks in a system, preventing any potential damage.

Key Components of a Compressed Air Pressure Switch

A compressed air pressure switch typically consists of several key components, each playing an essential role in its operation:

The Sensor: This component detects changes in pressure within the system. It may be a simple mechanical assembly or a more complex electronic sensor, depending on the type of switch.

The Diaphragm or Piston: These mechanical parts respond to changes in pressure detected by the sensor. When the pressure reaches a certain level, the diaphragm or piston moves, activating the switch.

The Switch: This component is a simple electrical switch that opens or closes a circuit in response to movement from the diaphragm or piston. When activated, it can start or stop a device, or trigger an alarm.

The Set Points: These are predetermined pressure levels at which the switch will activate. They can often be adjusted to suit the specific requirements of the application.

The Hysteresis: Also known as the switch’s ‘deadband’, this refers to the difference between the set point at which the switch turns on, and the set point at which it turns off. It prevents rapid on/off cycling that could potentially damage equipment.

How to Choose the Right Compressed Air Pressure Switch

Pressure range: Make sure the switch can handle the maximum and minimum pressure levels of your system.

Switch type: Consider the specific needs of your system and choose between a fixed or adjustable set point, as well as a single or dual switch design.

Electrical rating: Ensure that the switch’s electrical rating is suitable for your system’s power supply and can handle the load of any connected equipment.

Accuracy and precision: As mentioned earlier, accuracy and precision are crucial in pressure switches. Look for switches with a low hysteresis and high repeatability for reliable and consistent performance.

Environmental conditions: Consider the operating temperature and any exposure to chemicals or harsh environments when choosing a switch. Some models may be better suited for specific conditions than others.

Step-by-Step Guide on Installing a Compressed Air Pressure Switch

Disconnect Power: Safety first, always ensure the power supply is switched off before you start installing.

Remove Old Switch: If you’re replacing an old switch, remove it carefully. Make sure to remember or note down where all the connections go to.

Install New Switch: Place the new switch in the same position as the old one, aligning it correctly with the pressure system.

Connect Wires: Reconnect the wires to the new switch according to your notes from the old switch.

Secure the Switch: Secure the switch in place. Ensure it’s firmly attached to avoid any vibration issues.

Test the Switch: Once everything is connected, turn the power back on and test the switch to ensure it’s working correctly.

Basic Maintenance Tips and Best Practices

Regular Inspections: Regularly check the switch for any signs of damage or wear. Early detection can prevent more significant problems down the line.

Cleanliness: Keep the switch clean and free of dust or debris that can affect its performance.

Check Settings: Make sure the switch is set to the correct pressure range for your system. Incorrect settings could lead to issues.

Professional Service: If you notice any issues with the switch, it’s best to call in a professional to take a look. Attempting to fix it yourself could cause further damage.

Replacement: If the switch is older or has been causing issues, it may be time to consider a replacement. Regularly replacing parts can ensure your system runs smoothly.

Conclusion

Compressed air pressure switches are essential components in many industrial processes, ensuring safe and efficient operations. Understanding their basic principles, types, and factors to consider when selecting one will help you choose the right switch for your system’s needs. So if you’re in need of a pressure switch, be sure to keep these points in mind for optimal performance and longevity of your equipment.