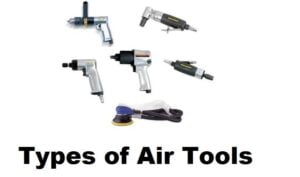

Air tools, also commonly known as pneumatic tools, are powered by compressed air and are widely used in various industries for tasks such as painting, polishing, sanding, and more. Their efficiency and power make them indispensable tools, but regular maintenance through cleaning and lubrication is critical for their optimal performance and longevity.

Even though we all know that all appliances should be cleaned and maintained for uttermost efficiency, it is often overlooked when it comes to air tools. Cleaning not only removes dirt and debris but also prevents rust and corrosion, allowing the tool to function smoothly.

Lubrication, on the other hand, means applying oil or grease to moving parts of the tool. This helps reduce friction and wear, ensuring longevity and efficient functioning of the tool.

Common Parts of Air Tools That Require Regular Cleaning

Air tools comprise various parts that require regular cleaning to ensure their optimal operation. Here are ten such components:

Air Inlet: The air inlet is where compressed air enters the tool, can become blocked with debris and requires regular cleaning.

Exhaust Port: The exhaust port is where used air is ejected. It can also accumulate dust and grime that need to be cleared.

Trigger: The trigger starts and stops the tool’s operation, needs to be kept clean to prevent jamming.

Cylinder: The cylinder, where the air expands to power the tool, may accumulate oil and dust residue that can impede operation.

Rotor Blades: The rotor blades, which spin to create the tool’s movement, can get dirty and decrease the tool’s efficiency.

Valves: The valves control the flow and direction of the air. Dirt or debris can cause these to stick, disrupting the tool’s operation.

Plungers: The plungers affect the tool’s motion, and any grime accumulation could hinder their function.

Bearings: Bearings, which support the tool’s moving parts, must be kept clean to ensure smooth rotation.

Air Line: The air line, which carries the air from the compressor to the tool, can become blocked if not regularly cleaned.

Piston: The piston, a crucial part of the tool that helps in generating motion, also needs periodic cleaning to remove any grime or residue.

Understanding The Importance of Regular Maintenance

At this point, we all know that air tools are powered by compressed air. Just to recap, an internal piston mechanism is put to work by this pressurized air, and it is this action that generates the motion used in various functions of the tool, such as drilling or grinding. Think of the piston as a tiny car engine. Like an engine, the piston in an air tool needs to move smoothly to operate efficiently.

But accumulation of grime or residue can impede this smooth motion, much like dirt in an engine can hamper its performance. That’s why cleaning the piston and other parts of the tool is so crucial.

Now, moving parts create friction, and friction can cause wear and tear. That’s where lubrication comes in. By lubricating the moving parts of the air tool, you can reduce this friction, leading to smoother operation and a longer lifespan for the tool. Just as you wouldn’t run a car engine without oil, you shouldn’t operate an air tool without proper lubrication.

In summary, below are the outstanding benefits of cleaning and oiling pneumatic tools:

- Improved Performance

- Longer Lifespan

- Cost Savings

- Reduced Downtime

- Better Efficiency

- Smoother Operation

- Enhanced Safety

- Prevents Rust and Corrosion

Types of Oil for Air Tools

There are various types of oil available in the market for lubrication of air tools, each with its own unique properties. Some commonly used oils include:

Mineral oil

Mineral oil is a derivative of crude oil and is the most widely used lubricant for air tools. It’s affordable, readily available, and works well in moderate temperatures. However, it tends to break down at high temperatures or under heavy loads, leading to increased wear on the tool’s internal parts.

Synthetic oil

Synthetic oils are man-made and designed specifically for lubricating air tools. They offer better performance and stability at high temperatures, making them ideal for heavy-duty or industrial use. However, they are more expensive than mineral oil.

Food-grade oil

Food-grade oils are safe to use in environments where contact with food is possible, such as in food processing plants. These oils have to adhere to strict regulations and guidelines to ensure that they are non-toxic and won’t contaminate food products.

Bio-degradable oil

Bio-degradable oils are environmentally friendly and break down easily without causing harm to the environment. They are often used in outdoor or marine environments where accidental spills can occur.

Choosing the Right Oil for Your Air Tool

When selecting an oil for your air tool, it’s important to consider factors such as the tool’s usage, operating temperature, and environment. Using the wrong oil can result in decreased performance and potential damage to your tool. It’s always best to consult with the manufacturer’s recommendations or seek advice from a professional to ensure you are using the correct oil for your specific air tool.

The Process of Cleaning Air Tools

Before we get into the actual process, let’s first gather the necessary materials for cleaning air tools:

- Clean cloth

- Wire brush

- Lubricant (preferably pneumatic tool oil)

- Compressed air

Steps for cleaning and lubricating air tools:

- Disconnect the tool from the air supply and release any remaining pressure.

- Use a clean cloth to wipe off any visible dirt or debris on the tool’s exterior.

- Use a wire brush to clean hard-to-reach areas such as crevices, joints, and corners.

- For stubborn dirt or residue, use a mild detergent and warm water to clean it off.

- Rinse the tool with clean water and dry it thoroughly with a cloth.

- Use compressed air to blow out any remaining moisture from the tool’s interior.

- Apply lubricant to all moving parts according to the manufacturer’s instructions.

- Reassemble the tool and test its functioning before storing it.

Frequency of Cleaning and Lubrication

The frequency of cleaning and lubricating air tools depends on the frequency of use. If the tool is used daily, then it should be cleaned and lubricated at least once a week. For less frequent use, cleaning and lubrication can be done every month or as needed. However, if the tool is used in harsher environments such as construction sites or workshops, it may require more frequent cleaning and lubrication.

Regularly cleaning and lubricating air tools not only improves their performance but also extends their lifespan. It prevents rust and corrosion from building up, ensuring that the tool stays in good condition for longer. Additionally, regular maintenance can save you money in the long run by preventing costly repairs or replacements.

Importance of Using the Proper Lubricant

It is important that you only use the appropriate lubricant on your compressor. Using the correct lubricant for your specific air tool is crucial to its efficiency and longevity. Pneumatic tool oil is designed specifically for air tools and provides better lubrication than general-purpose oils. It is important to avoid using other types of oils as they may not have the same properties and can cause damage to the tool.

If you use the wrong type of lubricant can also lead to a buildup of sludge and debris in the tool’s internal components. This can clog the air passages and affect its performance. It is important to always refer to the manufacturer’s instructions for recommended lubricants and follow them accordingly.

Maintaining Air Tools after Cleaning and Lubrication

Proper storage of air tools is key to their long-term maintenance. It’s advisable to store the tools in a dry, dust-free environment to prevent rust and dust buildup. Cleaning and lubricating should ideally be performed after every use, or at least once a month. Stay vigilant for signs like decreased performance or strange noises, which could indicate the need for maintenance.

Conclusion On Cleaning and Lubricating Air Tools

In conclusion, maintaining air tools through regular cleaning and lubrication is integral to their performance and lifespan. A little effort and diligence can go a long way in preserving these valuable tools, and adhering to a regular maintenance schedule ensures that they continue to serve you effectively and efficiently.